Protein Powder Dispenser

I designed and built a low-cost, automatic protein powder dispenser capable of delivering consistent portions. The prototype combined off-the-shelf components, 3D-printed parts, and everyday household materials, developed under strict budget and tool constraints.

Problem

As someone who enjoys an active lifestyle, I regularly use protein shakes to support my training.

❗I therefore noticed that conventional packaging makes dispensing inconvenient and messy, leading to powder-covered hands when scooping powder from the bag.

Solution

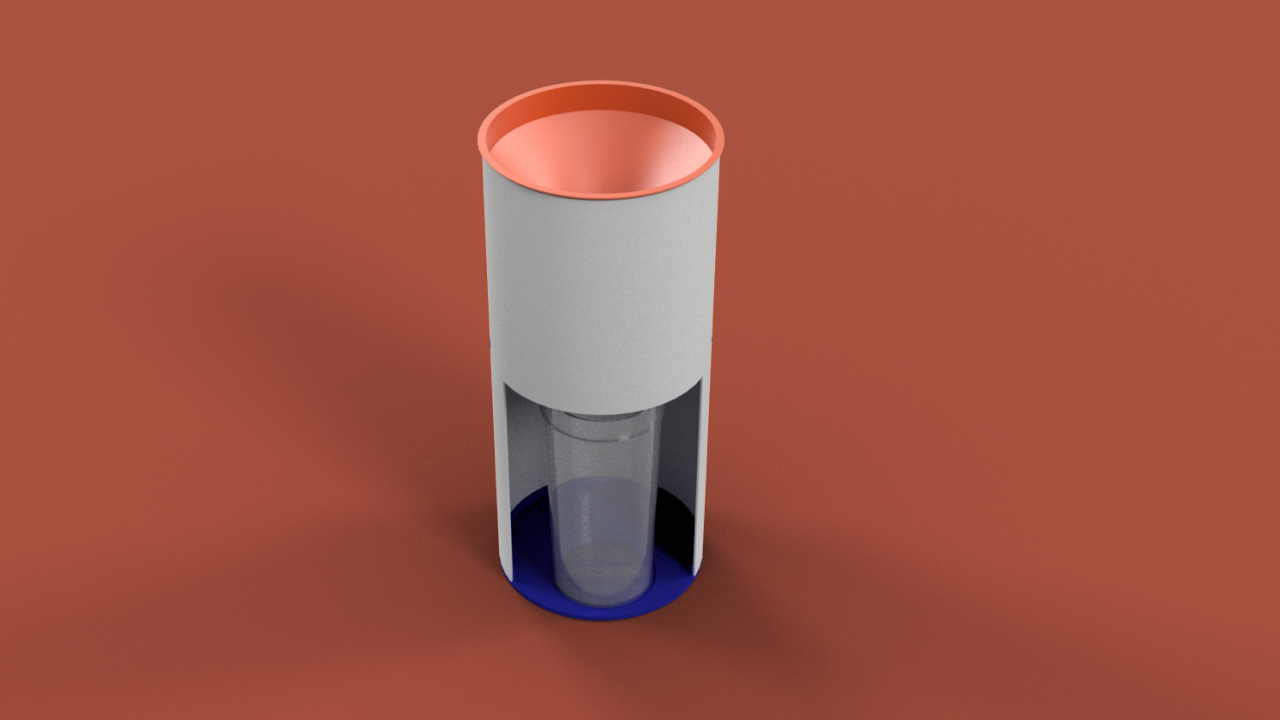

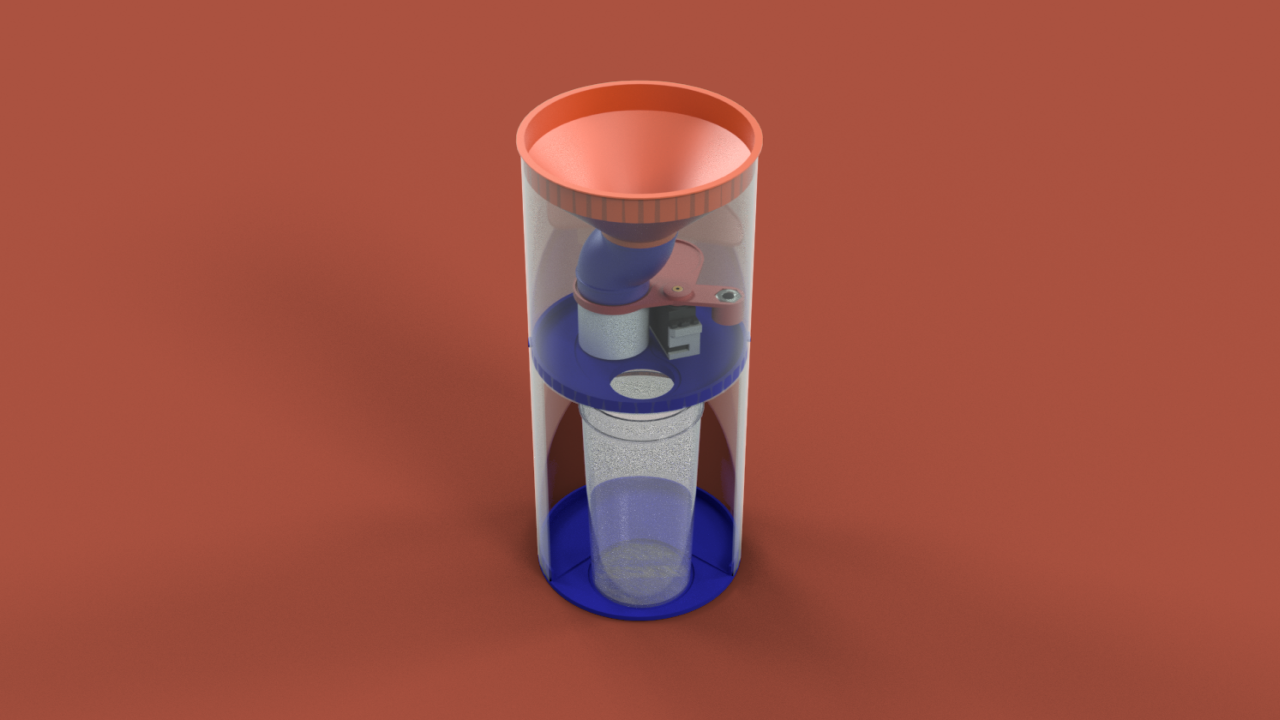

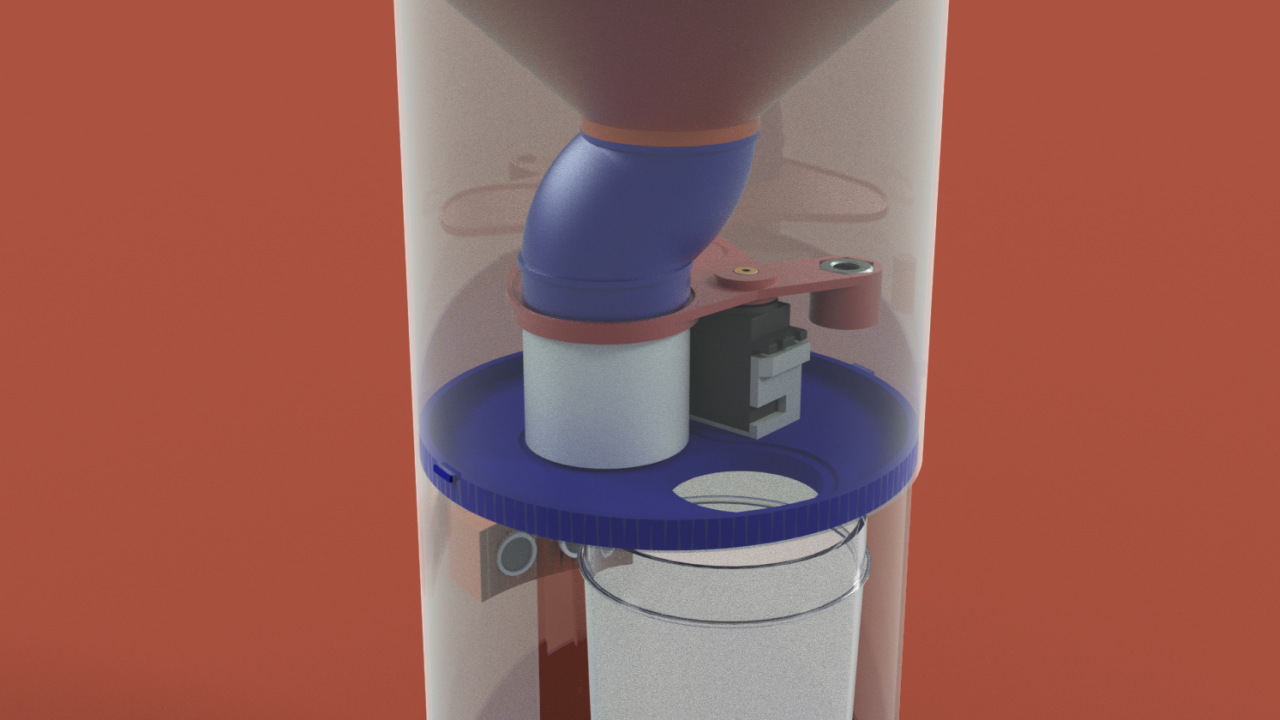

I developed a compact, home-friendly dispensing mechanism powered by a servo motor and ultrasonic sensor. The design used a rotating, counterweighted component to ensure smooth operation, with seals to prevent powder leakage. By integrating off-the-shelf parts with 3D-printed components, the dispenser was easy to assemble and maintain while staying low cost.

✅ A compact dispenser that delivers accurate protein powder portions with minimal mess and effort.

Process

The project followed an iterative, hands-on approach, moving quickly from crude prototypes and test code to refined CAD development and physical prototyping.

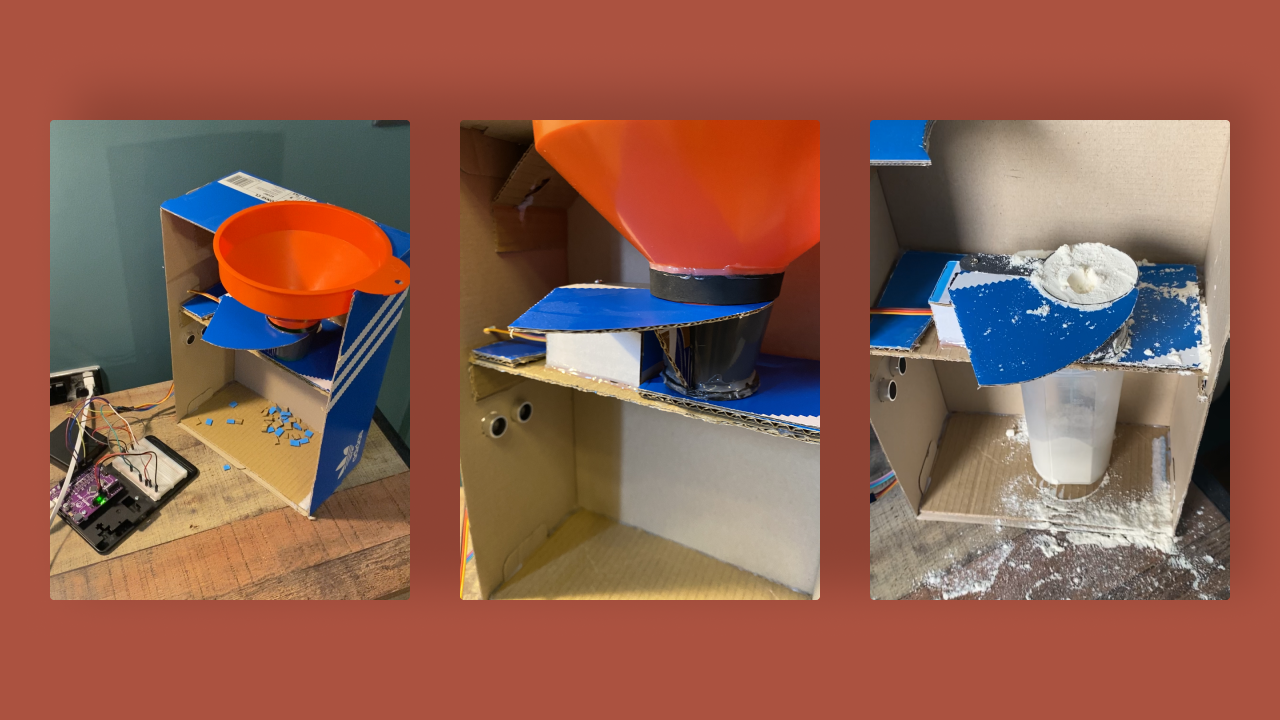

Rapid Prototyping

To validate the core dispensing concept, I built a simple cardboard mock-up driven by a servo motor. Using Arduino, I developed code to detect when a cup was placed via an ultrasonic sensor and trigger the servo. Through quick iterations, I refined the timing and movement until the mechanism operated reliably.

CAD Development

Once the concept was proven, I modelled the mechanism in CAD. This allowed me to incorporate counterweights for balance and refine the rotating component, while keeping the form factor compact.

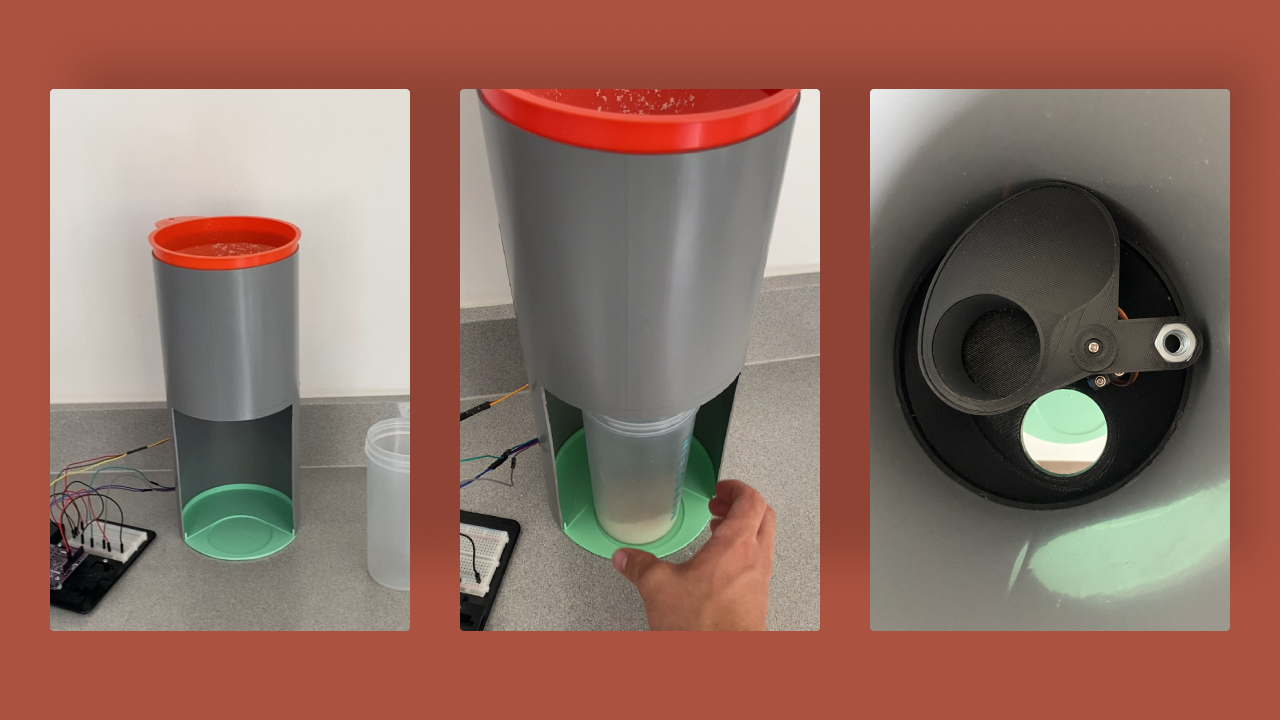

Prototype Testing

The working prototype successfully dispensed accurate portions of powder. Testing also revealed further opportunities for improvement, such as better powder containment, moisture protection, and integrated housing for electronics.